6-20 个字符(仅限字母加数字)

密码不一致

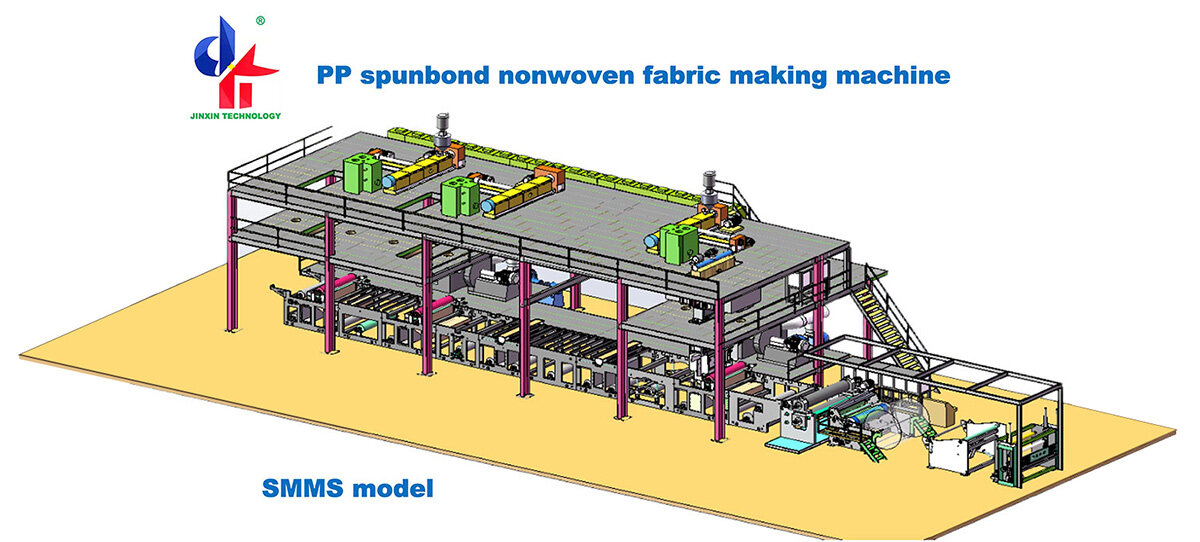

SMMS nonwoven machine

Spunbond, meltblown, spunlace, needling, dry papermaking (expanded paper), sewing, thermal bonding, chemical bonding, carding, netting, fiber pre-disposal, and other non-woven machinery and production lines; wet face towels, masks, surgical clothing, shaped masks, polymers, chemical fibers, special fibers, adhesives, foaming materials, coatin; and sanitary napkins for women, babies, and adults; as well as wet

| Model | JX-SMMS | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 50*16*12m | 50*18*12m | 50*22*12m |

| Mechanical Speed | 450m/min | 450m/min | 450m/min |

| Gram Weight | 10-120g/m2 | 10-120g/m2 | 10-120g/m2 |

| Daily Output | 8-12T/Day | 12-18T/Day | 18-24T/ Day |

| Transformer Capacity | ≈1200KVA | ≈1400KVA | ≈1900KVA |

| Power Consumption | 1200°-1850°Ton | 1200°-1850°Ton | 1200°-1850°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

SMMS PP spunbond nonwoven fabric machine

Raw Material

Polypropylene granule, masterbatch, additive.

Production process

A percentage of the polypropylene, masterbatches, and additive by high temperature the technology of air drawing into web-forming by negative pressure, then the process of calendar shape.

Products feature

Technological process very easy, and high output, no pollution, and no waste. possess of uniform cover, great intensity, good breathable features, and good feeling, etc.

Products Application

The product is used for packing, agricultural cover, and clothing packing. household, hotel accessories, medical health, etc.

What products can non-woven fabric-making machines be used to manufacture?

Non woven materials and deep processing technology and equipment: spunbond, meltblown, spunlace, needling, dry papermaking (expanded paper), sewing, thermal bonding, chemical bonding, carding, netting, fiber pre-disposal, and other non-woven equipment and manufacturing lines; Women's sanitary napkins, baby and adult diapers and diapers, wet face towels, masks, surgical clothing, shaped masks, polymers, chemical fibers, special fibers, adhesives, foaming materials, coatings, extenders, non-woven Color Masterbatch, resin and other deep processing equipment, coating, lamination, electrostatic application (electret), electrostatic flocking, molding, packaging, and other equipment.

Industrial fabrics and related deep-processing products: Medical hygiene materials, indoor decoration materials, new building, and waterproof materials, labor protection products, environmental protection materials, filter materials, new cold protection materials, and clothing accessories industrial materials, agricultural materials, automobile materials, packaging materials, and coating base fabrics, Geotextiles and geosynthetics.

Nonwoven fabrics and deep processing products: geotextiles, construction fabrics, automotive fabrics, agricultural fabrics, synthetic leather base fabrics, filter materials, building materials, electrical insulation materials, environmental protection products, paper, blankets, medical and health products, decorative products, clothing products, shoe materials, household products, and other multi-functional non-woven fabrics. Spunbonded, melt blown, needled, Spunlaced, heat bonded, chemically bonded nonwovens and their finished products.

Raw materials and auxiliary materials: polymers, chemical fibers (polyester, polypropylene, nylon, nylon, viscose staple fiber, etc.), special fibers, adhesives, foaming materials, coatings, extenders, color masterbatch; Manufacturing equipment and processing plan: nonwoven manufacturing equipment: nonwoven equipment and manufacturing line, finishing equipment, deep processing equipment, auxiliary equipment, and instruments.